Electrical or thermal conductivity between the components they seal together is provided by conductive adhesives. The adhesives achieve this conductivity by combining metal flakes and powders with either single elements or two-part epoxy or glue. Several metals, including silver, nickel, copper, and silver-coated nickel, can be used to make conductive adhesives. Read More…

Master Bond formulates high quality adhesive systems to help engineers meet specific requirements for their bonding, sealing, coating and encapsulation applications. The product line consists of epoxies, silicones, UV curable and LED curable systems that feature outstanding performance properties.

We hold North American manufacturing together with our adhesives! We have presences in Seattle, Portland, Spokane, Houston, Dallas, Tulsa, Chicago and many others so that we will be where you need us, always! Our motto states that “We strive for insanely happy customers,” and that’s exactly what the kind of commitment to excellence that we will bring to you. For more information on what we...

We hold North American manufacturing together with our adhesives! We have presences in Seattle, Portland, Spokane, Houston, Dallas, Tulsa, Chicago and many others so that we will be where you need us, always! Our motto states that “We strive for insanely happy customers,” and that’s exactly what the kind of commitment to excellence that we will bring to you. For more information on what we...

More Conductive Adhesive Manufacturers

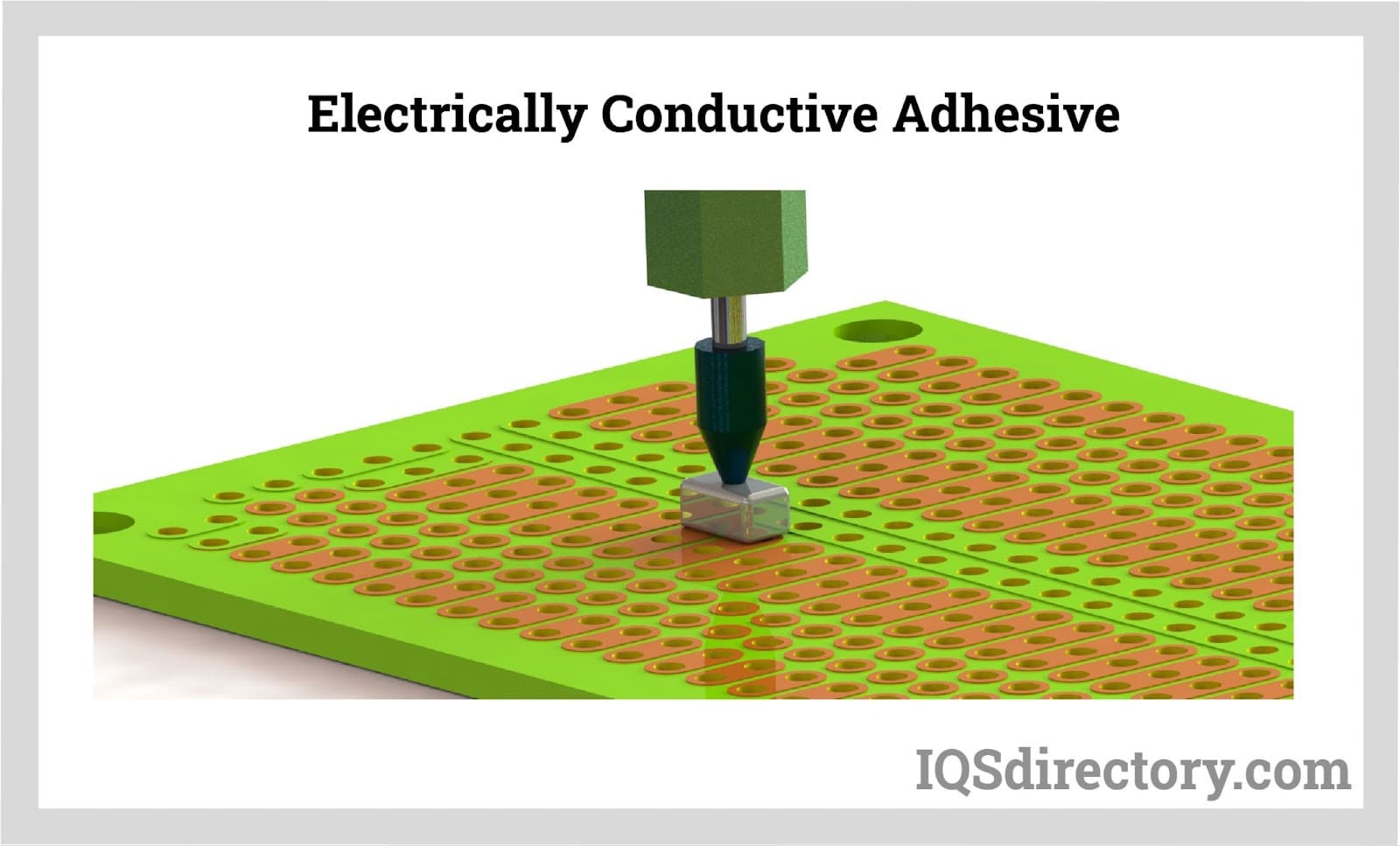

For a broad range of electronics manufacturing and electrical assembly applications where metallic additions are undesirable, advanced graphite adhesive formulations have been developed as a solution. Silver-based conductive adhesives deliver the highest electrical conductivity, while nickel, copper, and graphite fillers offer specialized properties for unique requirements. Electrically conductive adhesives—sometimes referred to as ECAs—can be applied in precision dots or lines to efficiently link two components electrically, making them integral in modern circuit board assembly, sensor attachment, and microelectronics.

The curing process for these adhesives is highly versatile, with options including thermal (heat) curing, UV light curing, and moisture curing, catering to diverse production environments. Material is typically heated until molten during the heat-curing process and then allowed to cool, which forms hot melt adhesives—a popular subset of epoxy-based glues. In contrast, UV light curing adhesives initiate rapid polymerization and hardening under controlled UV exposure, providing instant set times and high throughput for automated lines. Moisture curing involves a chemical transformation triggered by environmental humidity, making it ideal for field repairs and environments where heat or UV exposure is impractical.

Curious about which curing method is best for your application? Explore the differences between heat, UV, and moisture-cured conductive adhesives to optimize your assembly process for speed, bond strength, and material compatibility.

Materials Used in Conductive Adhesives

Understanding the composition of conductive adhesives is critical for selecting the right solution for your electronic assembly, thermal management, or EMI shielding needs. The primary materials include:

- One-component adhesives and multicomponent epoxy adhesives are widely available, offering varied shelf life, processing requirements, and performance characteristics. One-component systems are favored for ease of use and reliability in automated lines, while multicomponent epoxies provide customizable properties for demanding applications.

- Conductive fillers such as silver, nickel, copper, and graphite impart unique electrical and mechanical properties. Silver is prized for its unmatched conductivity and is the industry standard for high-performance ECAs. Nickel and copper offer cost-effective alternatives, while graphite is preferred for non-metallic, corrosion-resistant assemblies.

- The silicone, synthetic resin, or varnish base acts as the adhesive matrix, influencing the bonding strength, flexibility, and resistance to environmental factors. The type and loading of conductive filler directly affect the volume resistivity and overall adhesive performance.

- Modern electrically-conductive adhesives often employ thermosetting resins combined with metallic fillers to achieve exceptional reliability, especially in surface mount technology (SMT), flexible circuits, and wearable electronics.

- Polymer/silver flake composites are increasingly popular in the miniaturization of electronic devices due to their excellent flexibility, low curing temperatures, and compatibility with heat-sensitive substrates such as plastics and thin-film materials.

Want to compare silver conductive adhesives versus graphite-based adhesives? Learn how each material impacts conductivity, cost, and environmental resistance for your specific use case.

How are Conductive Adhesives Made?

The performance of a conductive adhesive is rooted in its manufacturing process and the purity of its constituents. Here’s a closer look at how leading manufacturers create these advanced bonding solutions:

- Silver content often makes up as much as 80% of the bulk in premium electrically-conductive adhesives, delivering superior signal integrity and low resistance paths essential for high-speed electronics and RF applications.

- The conductive filler is uniformly suspended within the adhesive base, ensuring a reliable network for electron flow. This suspension process is carefully engineered to prevent filler agglomeration, which could compromise conductivity and mechanical strength.

- Electrical conductivity is enabled by the contact between individual filler particles, forming continuous conductive pathways through the cured adhesive matrix.

- Properties such as flexibility, thermal conductivity, moisture resistance, and viscosity are tailored through the choice of base resin, curing method, and filler composition, enabling adhesives to meet a wide range of application requirements from PCB repair to thermal interface materials (TIMs).

- Common base resins like epoxy (typically formulated from Bisphenol-A and epichlorohydrin) deliver strong bonds and exceptional resistance to humidity and harsh environments, ensuring long-term reliability in mission-critical electronics.

Are you evaluating thermally conductive adhesives for your next project? Discover the manufacturing differences between standard ECAs and adhesives designed for high thermal transfer, such as in power electronics, LEDs, and heat sink bonding.

Working of Conductive Adhesives

Conductive adhesives function by forming a matrix of electrically conductive particles within a polymer binder. When applied between two substrates, this matrix allows for the efficient passage of electrical current—typically in the milliampere range—making them ideal for grounding, signal transmission, and static dissipation.

- Common conductive components include metalized fiber webs, silver or nickel particles, and other advanced metallic or carbon-based fillers, each selected for their unique electrical and mechanical profiles.

- The resistivity of the adhesive—its ability to conduct or resist electrical current—is determined by both the type and arrangement of the conductive fillers, as well as the overall adhesive formulation.

- Anisotropic Conductive Adhesives (ACAs), also known as Z-axis adhesives, conduct electricity in one direction only, making them perfect for fine-pitch connections in LCD assembly and flexible printed circuits (FPCs). Isotropic Conductive Adhesives (ICAs) conduct in all three axes (X, Y, Z), supporting a broader range of connection geometries and multi-directional current paths.

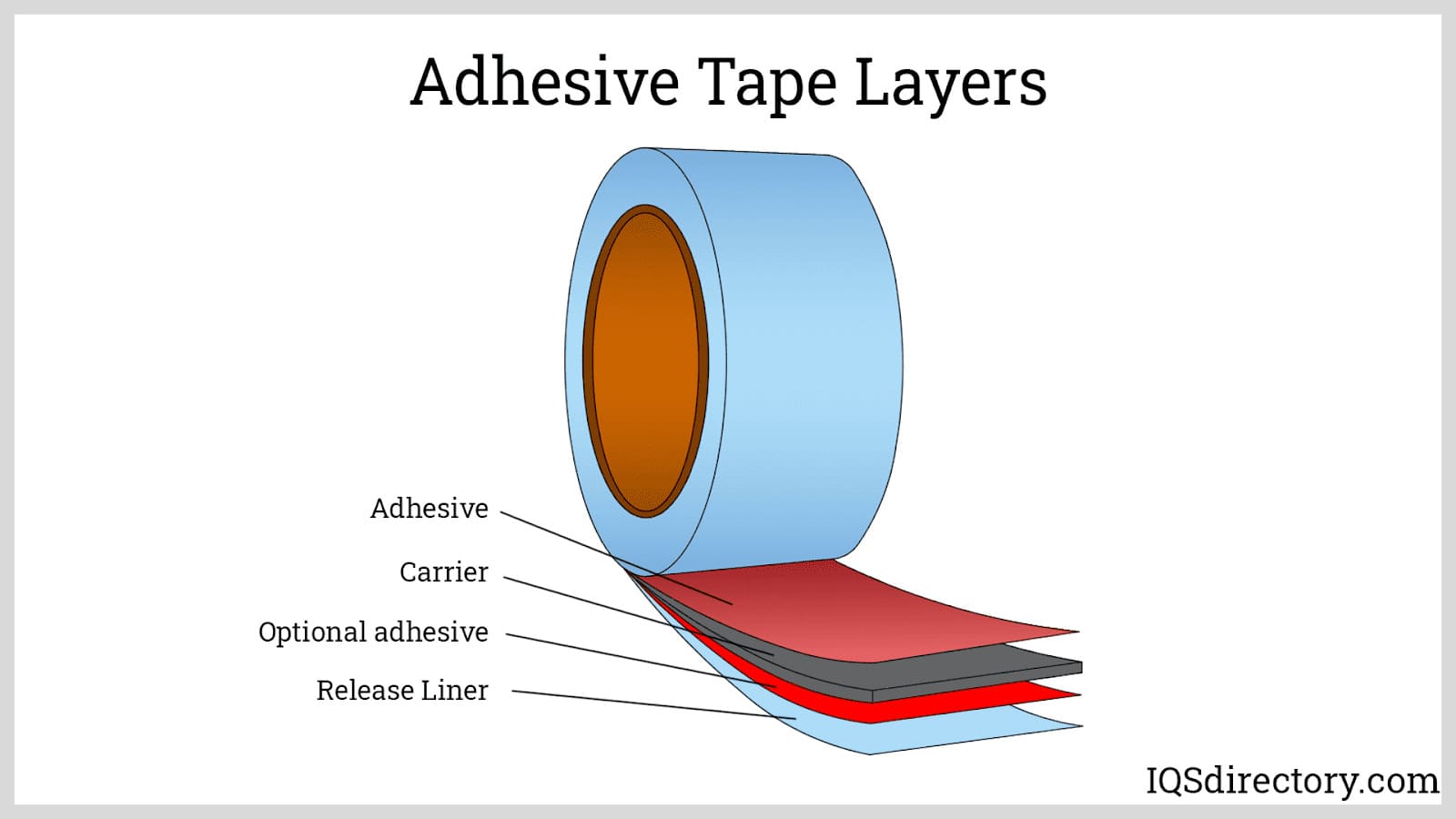

- These adhesives are available in various forms, including tapes, pastes, and films, to suit manual, semi-automated, and fully automated assembly processes.

Need to determine whether anisotropic or isotropic conductive adhesives are best for your application? Compare their electrical performance, application methods, and compatibility with your assembly design.

Benefits of Conductive Adhesives

Modern conductive adhesives offer a host of benefits over traditional soldering and mechanical fastening methods, supporting innovation in electronics design and manufacturing. Key advantages include:

- Low-temperature processing: Conductive adhesives enable reliable electrical connections at temperatures below standard soldering, protecting sensitive components and substrates from heat damage—a major advantage in flexible electronics and wearable devices.

- Vibration and shock resistance: The inherent flexibility of many electrically-conductive tapes and adhesives allows bonded assemblies to absorb mechanical stress, reducing the risk of connection failure in high-vibration environments such as automotive, aerospace, and industrial equipment.

- Lightweight and streamlined designs: By replacing bulky mechanical fasteners, conductive adhesives support compact, lightweight assemblies and innovative enclosure designs. This is especially valuable in consumer electronics, medical devices, and IoT sensors.

- Versatile application: Conductive adhesives are easily dispensed by hand, automated equipment, or die-cutting systems, supporting high-volume manufacturing and rapid prototyping with minimal cleanup and waste.

- Broad substrate compatibility: These adhesives can bond a wide variety of materials—including metals, plastics, ceramics, and composites—enabling hybrid assemblies and advanced packaging solutions.

Looking for ways to maximize production efficiency and assembly reliability? See how conductive adhesives can replace soldering or mechanical fasteners in your current workflow for improved performance and lower total cost of ownership.

Applications of Conductive Adhesives

Electrically-conductive adhesives are indispensable across a spectrum of industries and applications, offering solutions where traditional soldering or mechanical fastening may not be feasible. Common use cases include:

- Electronics and Electrical Industries: The largest consumers of conductive adhesives, using them for PCB assembly, chip bonding, and interconnects in consumer electronics, automotive electronics, and industrial controls.

- Medical Devices: Used in the assembly of medical electrodes, sensors, diagnostic equipment, and hearing aids, where biocompatibility, flexibility, and reliable electrical performance are paramount.

- Thermal Management: In heat sink attachment, power electronics, and LED modules, thermally conductive adhesives enhance heat dissipation while providing strong, electrically conductive bonds.

- EMI/RFI Shielding: Used to bond EMI (electromagnetic interference) and RFI (radio-frequency interference) shields to enclosures, ensuring signal integrity and regulatory compliance in sensitive electronics.

- Static Dissipation: Specialty adhesives are formulated for ESD (electrostatic discharge) flooring, antistatic workstations, and protective packaging to prevent static buildup that could damage sensitive components.

- Automotive and Aerospace: Used for sensor mounting, circuit repair, and lightweight assembly in high-reliability, high-vibration environments.

- Flexible and Printed Electronics: Enable the creation of wearable technology, smart labels, and flexible displays, supporting next-generation electronics design.

- Die Attachment and Solder Masking: Provide critical bonding and electrical connection in semiconductor packaging and microelectromechanical systems (MEMS).

Have a unique application in mind? Contact us to discuss custom conductive adhesive formulations for your specific industry or product requirements.

Choosing the Proper Conductive Adhesive Manufacturer

Selecting the right conductive adhesive supplier is crucial to achieving the desired balance of conductivity, bond strength, durability, and cost-effectiveness. Here are best practices to guide your procurement process:

- Compare multiple suppliers: To ensure you receive the most competitive pricing and technical support, evaluate at least 4 to 6 conductive adhesive manufacturers using our comprehensive supplier directory. This allows you to benchmark quality, performance, and lead times.

- Review company profiles: Each manufacturer’s business profile highlights their core competencies, certifications (such as ISO 9001, RoHS, or REACH compliance), and industry experience—helping you identify partners with proven expertise in your market sector.

- Request technical data and samples: Utilize the contact forms provided to request detailed technical datasheets, safety information, and product samples. This enables robust evaluation and in-house testing before making a bulk purchase.

- Assess support and customization: Leading conductive adhesive suppliers can tailor formulations for unique requirements, such as enhanced thermal conductivity, lower outgassing, or improved flexibility for dynamic applications. Discuss your project needs directly with technical representatives.

- Use our RFQ system: Streamline your procurement by submitting a single Request for Quote (RFQ) to multiple suppliers through our platform, saving time and ensuring you receive the best value offers.

Ready to source conductive adhesives for your next project? Start by browsing our curated list of leading manufacturers, review their capabilities, and reach out for tailored quotes and technical advice. For more information on conductive adhesive selection, application techniques, or industry standards, explore our Adhesives Resource Center.

Frequently Asked Questions about Conductive Adhesives

- What is the typical resistivity of a high-performance conductive adhesive?

Resistivity varies by formulation and filler loading, but high-performance silver-filled adhesives can achieve values as low as 1x10-4 Ω·cm. Lower resistivity equates to higher electrical conductivity, making these adhesives suitable for sensitive signal transmission and grounding. - Can conductive adhesives replace solder in all applications?

While ECAs offer many advantages, they may not fully replace solder in high-temperature or high-current applications. They excel in low-temperature, fine-pitch, flexible, and sensitive assemblies where solder is impractical or damaging. - Are conductive adhesives compatible with automated assembly?

Yes, modern conductive adhesives are engineered for compatibility with screen printing, jet dispensing, and automated pick-and-place systems, supporting high-volume, repeatable production. - How do you ensure long-term reliability in harsh environments?

Choose adhesives with proven resistance to moisture, thermal cycling, vibration, and chemical exposure. Look for third-party testing data and certifications for mission-critical applications.

Still have questions? Ask our experts for guidance on conductive adhesive selection, testing, and best practices for your specific industry or application.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services